High-tech perfector press in Lower Bavaria

Ortmaier-Druck invests in the future with Rapida 106

Frontenhausen is actually well-known in many parts of Germany – as the film set for a series of popular crime mysteries written by author Rita Falk. If you know Niederkaltenkirchen, then you could probably find your way around Frontenhausen. Fans who pay close attention will also know the historical premises of Ortmaier-Druck, even though it is only the company letterbox which features in the films. The company still produces just a few 100 metres from the centre of the quiet little town, albeit in the meantime with an eight-colour Rapida 106 with perfecting unit for 4-over-4 production and an additional coater.

“It’s unbelievable how it races through the jobs,” was one of the first comments which Stefan Ortmaier made about his new press. Together with his brother Rainer, he represents the third generation to hold the reins of the company. To date, they have been using two shorter medium-format Rapidas. One now remains, for the 1/1, 4/0 or 4/1 jobs. The important task for the future is to keep the work coming in for the new press, for example with jobs from the online portal flyerpara.de, for resellers and for a number of renowned industrial customers, most of whom are based within a radius of approx. 100 km.

Ortmaier is currently in the process of reorganising its pre-press, print and post-press operations, including the associated stores. Production is to be optimised on the basis of defined processes and short distances. The market in which the company is active is characterised by intense price competition. With the Rapida 106 perfector, however, it is well equipped to tackle all coming challenges. A new process-free platesetter, a StitchLiner and new cellophaning equipment also contribute to the optimism.

Frontenhausen is proud of its role as the film set for crime mysteries with cult status

Full-service support for customers

Alongside classic commercial printing, Ortmaier offers a variety of advertising materials and textile printing services, as well as producing the Vilstalbote, a weekly advertiser with a circulation of 120,000 copies. This combination of different services is well received by the customers. Another key factor is the offer of personal advice and that certain extra in terms of customer service, which sets Ortmaier apart from many online print portals, for example. The printing business accounts for 110 employees, with another 60 working for the Vilstalbote.

There were plenty of reasons to invest in a new sheetfed offset press. Competitiveness stood very high on the list. It is imperative for 4/4 jobs to be printed in a single pass, even including finishing where necessary. Extensive automation and parallel processes at job changeover also enable significant makeready savings. The latter point is especially important in connection with short runs. Thanks to the improved cost framework, furthermore, Stefan Ortmaier expects to attract a whole series of new jobs.

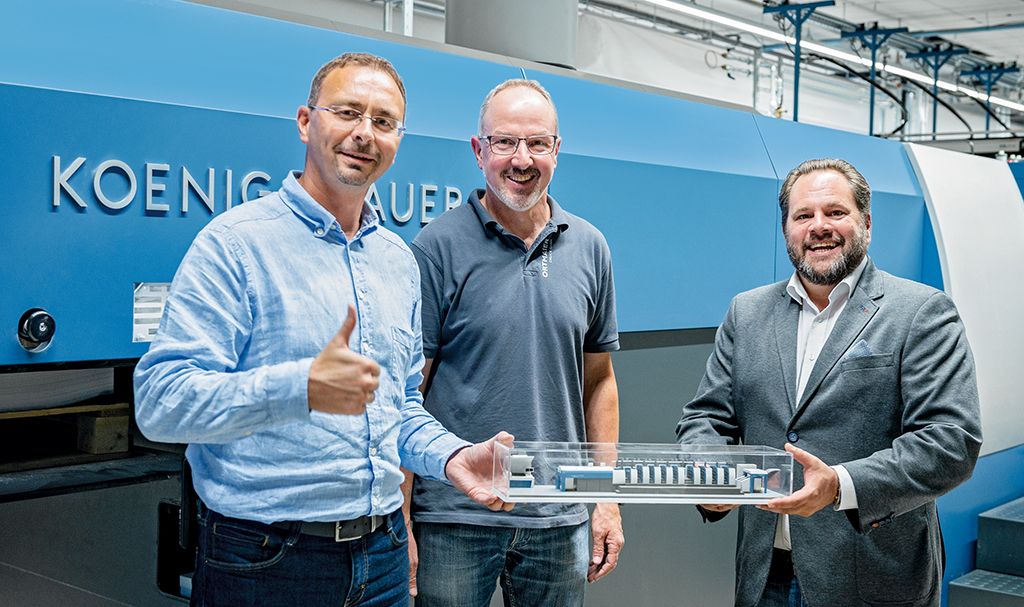

Stefan Ortmaier (left) and Andreas Huber (centre) received a model of the new Rapida 106 from Gavin Elflein of Koenig & Bauer (DE)

Largest single investment in the company’s history

The new Rapida 106 is at the same time a signal. It is the largest single investment in the company’s 50-year history. And from the technological perspective a quantum leap: This is not merely a replacement investment – the whole company workflow has been reorganised.

It is particularly important for the employees to see that the company is investing. Andreas Huber, head of production, is delighted: “You can feel the enthusiasm. This is an absolutely mature press.” The company is now printing on the “newest of the new”. There is no other similarly equipped eight-colour medium-format press within a more than 50 km radius.

Printer Marco van Laak enjoys working on the fully automated eight-colour press with 4/4 perfecting and an additional coating unit

Continuous further optimisation is adding the final touches to the performance of the Rapida 106. Stefan Ortmaier estimates that it is already exploiting over 80 per cent of its potential. The printers benefit from their many years of experience with this press type. The change of generation was soon mastered, and the secrets of perfecting were quickly unravelled. The many automation features simplify work processes and relieve the press operators of routine tasks.

A number of decisions relating to process organisation will soon be contributing to further increases in productivity. Stefan Ortmaier looks ahead optimistically. “Our business approach is very similar to that of Koenig & Bauer,” he says. In this respect, too, there is a sound foundation for further good cooperation between the two companies.

Inline colour control with QualiTronic ColorControl further simplifies the production process

Martin Dänhardt

Background photo: The long perfector was the first press at Ort-maier-Druck to be fitted with an automatic ink supply