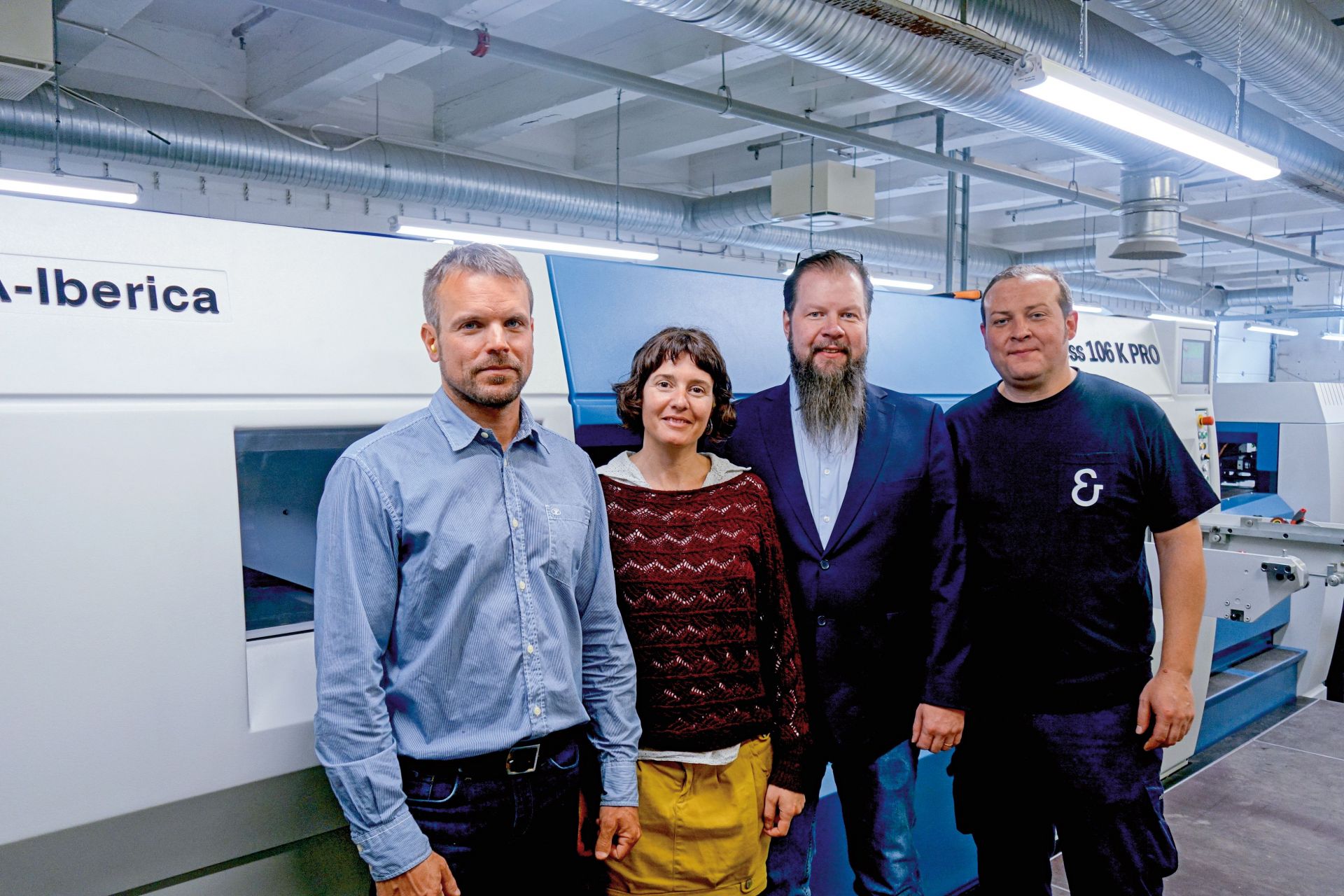

Orapac invests in Ipress 106 K PRO

Finnish boxmaker completes a

€4 million investment programme

The small coastal town of Oravais, some 450 kilometres north of the Finnish capital Helsinki, is the home of Orapac, a highly efficient box production company which specialises in the litho-lam production of E- and F-flute corrugated packaging. Orapac was founded in 1990 and is today managed by Fredric Tidström. He and his staff of 25 work primarily for the international markets of its export-orientated customers – Finland itself having only a small volume requirement from its population of 5.5 million.

The early days saw print production carried out on two-colour presses, before moving into multi-

colour production to cater for changing market demand. On the corrugated side, Spanish manufacturer IOBox was the preferred choice for litho-laminators back in 2005 and again in 2013 – but the one manufacturer which has enjoyed consistent faith from Orapac over the years is Iberica, from whom the company has acquired five die-cutters in total – the latest being an

Ipress 106 K PRO model, installed at the beginning of 2019.

Managing director Fredric Tidström explains: “More than 90% of our output is E-flute laminated with offset printed sheets – F-flute and cartonboard make up the balance. One of our key requirements has always been solid reliability from a heavyweight machine capable of handling corrugated board. We originally chose an Iberica LM55 and have progressed through their range as the years have gone by. Reliability and great after-sales support have been key to our staying with the brand, even after looking closely at what the competition had to offer each time. Compatible tooling from having two machines from the same manufacturer is a strong factor, as is operator familiarity.”

The tooling of the latest machine is a perfect fit for the previous Speed 105 K which was installed in 2015. Both possess stripping and blanking sections. Based on well-proven technology, the

Ipress 106 K PRO combines high performance with flexibility and fine control over a range of substrates. Significantly, it is equipped with the same DriveTronic feeder as the Rapida offset presses, which guarantees perfect alignment at the infeed. Control is via a touchscreen which facilitates fast registration, while the anti-static feed table reduces downtimes.

The DriveTronic feeder is just like the one used on high-performance sheetfed offset presses of the Rapida series

Reliable packaging production

From a historical point of view, the background to Orapac is quite unusual and began when the neighbouring company Mirka, an international manufacturer of cleaning products and tools for the industrial market, became dissatisfied with its existing supplier of packaging and asked Orapac if it could do better. The partnership has endured and has grown continuously to the benefit of both parties. It provides Orapac with regular business and Mirka with reliable local production and instant call-off from an adjacent warehouse. Longstanding experience and cooperation creates an even workflow for Orapac and balances any seasonal fluctuations in demand.

“There is no doubt that the extraordinary synergies for our two businesses improve day-to-day operations. We share an ERP system, and by having our computers linked, we can keep supplies at a pre-agreed level and guarantee delivery of 100% accurate boxes. We load into the shared warehouse and their forklift truck drivers take what they want when they need it – it’s very simple and very effective,” says Tidström.

Aside from Mirka, most of Orapac’s output is for the international industrial markets. An increasing level of business is being enjoyed from the drinks sector, while food packaging represents a relatively low proportion of turnover. According to Tidström, typical jobs fall in the 1,000 to 30,000 box range, with 3,000 being a reasonable average: “That probably means about 1,000 sheets, so one and half pallets, which tells you how many job changes we do per shift. This is where simple and fast makeready of the press and die-cutter is so important.”

Left to right: Fredric Tidström, CEO Orapac; Amanda Ràmia, marketing & communications, Koenig & Bauer Iberica; Jan Vesterberg, technical sales, Convertec; David Liginfer, service instructor, Koenig & Bauer Iberica

The laminating equipment is also from Spain

Production in historical surroundings

Next on the investment list is a logistics system to improve workflow in the production facility, a beautifully preserved building which started life as a farm in the 1760s and was a textile factory in the 19th century. Its multi-floored construction with many supporting pillars makes for a rather fragmented production layout. Tidström is looking for a way to automate the handling of work-in-progress to allow him to re-deploy his staff to more productive tasks.

“We’re fully aware that the condition of the sheets on the pallets affects the performance of the downstream machines. That’s why we try to stack-down for 24-36 hours after printing and aim for a maximum of 20% humidity in the printed stacks prior to die-cutting. We have invested heavily in humidifiers to keep the production environment at a constant level,” he comments. The plant in Oravais currently operates a single shift pattern five days a week, and according to Tidström, this was made possible by the extra efficiency of his new die-cutter and new press. “We can now produce as much in one shift as we used to do in two – that’s progress – and highlights what new technology can do.”

Industry recognition

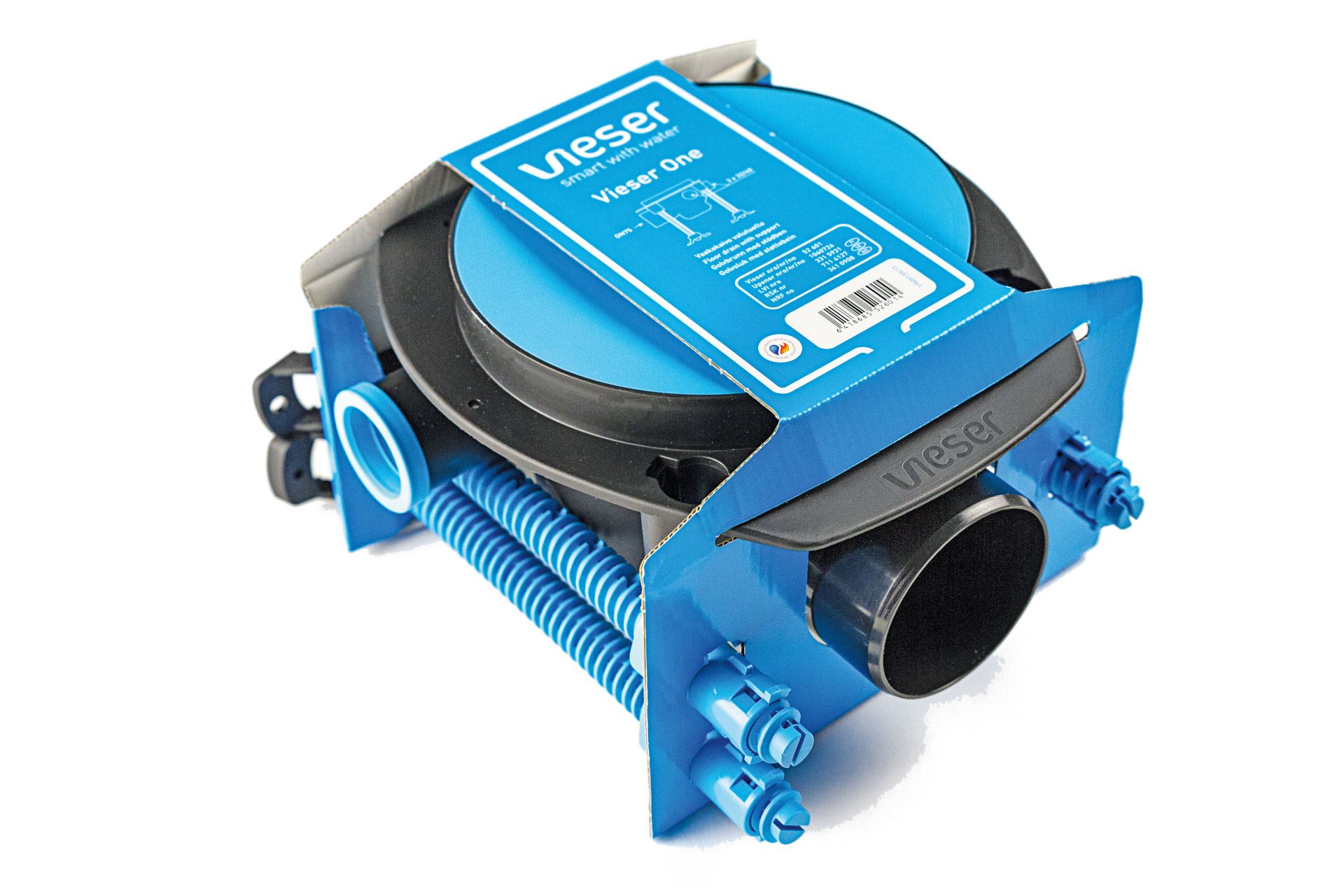

A WorldStar Packaging Award for an innovative and cost-effective packaging design for Vieser One highlights Orapac’s capability from design to delivery. An industrial drainage product needed a pack design that was easy to assemble, attractive and allowed the consumer access to the product to feel its quality. The pack in question is just one of a number of clever designs that the company has created over the years.

Looking from the outside, there is no doubt that Orapac is well set up and professionally managed, albeit with a rather unusual, yet mutually beneficial relationship with its biggest customer. Tidström was clever in spotting a niche opportunity and then defining the most efficient way of taking it. Any other company of this size might justifiably baulk at the thought of a €4m ($4.4m) investment plan, but because of its unique commercial situation, Orapac can take full advantage and still have capacity to diversify its business into other markets.

Award-winning product: Packaging for Vieser One

Examples from the Orapac product portfolio

Nick Coombes

Questions:

Amanda Ramia

Background photo: The Ipress 106 K PRO stands out with solid reliability in the die-cutting of corrugated board