New production hall and new technology for Schmidt & Buchta

In eager anticipation of the Rapida 76

Matthias Herrmann, managing director of the printing company Schmidt & Buchta in the small North Bavarian town of Helmbrechts, visited Koenig & Bauer Grafitec in July to learn more about the factory in which his Rapida 76 was being manufactured. At the end of a tour through the assembly centre, he came to a press which was printing at maximum production speed: His press! It welcomed him with an individually designed poster – and the future owner was visibly moved!

In the meantime, the five-colour Rapida 76 with coater and extended delivery is presumably in daily production. The company also invested in a 1,000m2 (10,800sq.ft) production hall. That both investments were possible at the same time is attributable to the good reputation which Schmidt & Buchta enjoys on the market, and to the managing director’s positive approach to the future. It was tax consultant Marco Matus who recommended rolling the two projects into one. And with Elbe-Leasing, Schmidt & Buchta was assisted by a finance provider with profound knowledge of the branch.

Alongside commercial products of all kinds, Schmidt & Buchta produces so-called “sample hangers”, which are used in the textile industry to present fabric samples to fashion companies or at trade fairs. Another spotlight field is that of business reports, which are even printed in offset in tiny runs of just 15 to 25 copies if the customer so wishes.

Benjamin Nelles (left) explains the quality documentation for the Rapida 76 to Matthias Herrmann (2nd from right)

Flexible in half format

To underpin a product portfolio which could hardly be more diverse, Schmidt & Buchta is dependent on maximally flexible technology, not least because the Rapida 76 is the company’s only half-format production press. Substrates from 40 to 700gsm (27 to 473lbs) must be printed reliably and in high quality. The same demands apply to coatings, e.g. drip-off effects, inline die-cutting and perforation via the coating tower.

A high level of automation is an important feature of the Rapida 76. Accordingly, the selected press configuration includes practically everything which contributes to fast job changes. In addition, it incorporates essentially gapless quality monitoring. Quali-

Tronic PDF combines three valuable functions in one system: Inline colour control, including LiveView for direct viewing of the camera images, sheet inspection for production monitoring, and comparison of the printed sheet with a pre-press PDF.

Even the purchasing of the press took a somewhat unusual course. It was Matthias Herrmann himself who contacted the manufacturer to enquire about a suitable solution. Arguments which attracted him to Koenig & Bauer were the innovative engineering concept of the Rapida 76, the comprehensive functionality of the press console, and the option of a PDF check, a feature which is otherwise rarely encountered in the half-format class. The general interest in Koenig & Bauer was quickly reinforced by the feeling that he could rely on competent support from the manufacturer’s employees. “In the end, it was print instructor Benjamin Nelles who sold the press,” says Matthias Herrmann, remembering their numerous print demonstrations together.

Red carpet treatment in front of the new Rapida 76 for Matthias Herrmann (centre), his tax consultant Marco Matus (2nd from left) and Thomas Grübner from Elbe-Leasing (4th from left), pictured with staff from the factory

Optimistic view ahead

The Rapida 76 will secure a competitive advantage for Schmidt & Buchta for several years to come. It is almost certainly the most highly automated sheetfed offset press in this format class in the region. And Matthias Herrmann is convinced that this will help him to win over more than just one or two new customers along the way.

The positive attitude displayed by print entrepreneur Matthias Herrmann is truly exemplary and sends everyone involved with him into raptures: His finance provider, his suppliers and the press manufacturer. It was thus no surprise that, when asked where he saw himself in five or six years, his spontaneous answer was: “Back here in Dobruška, of course!”

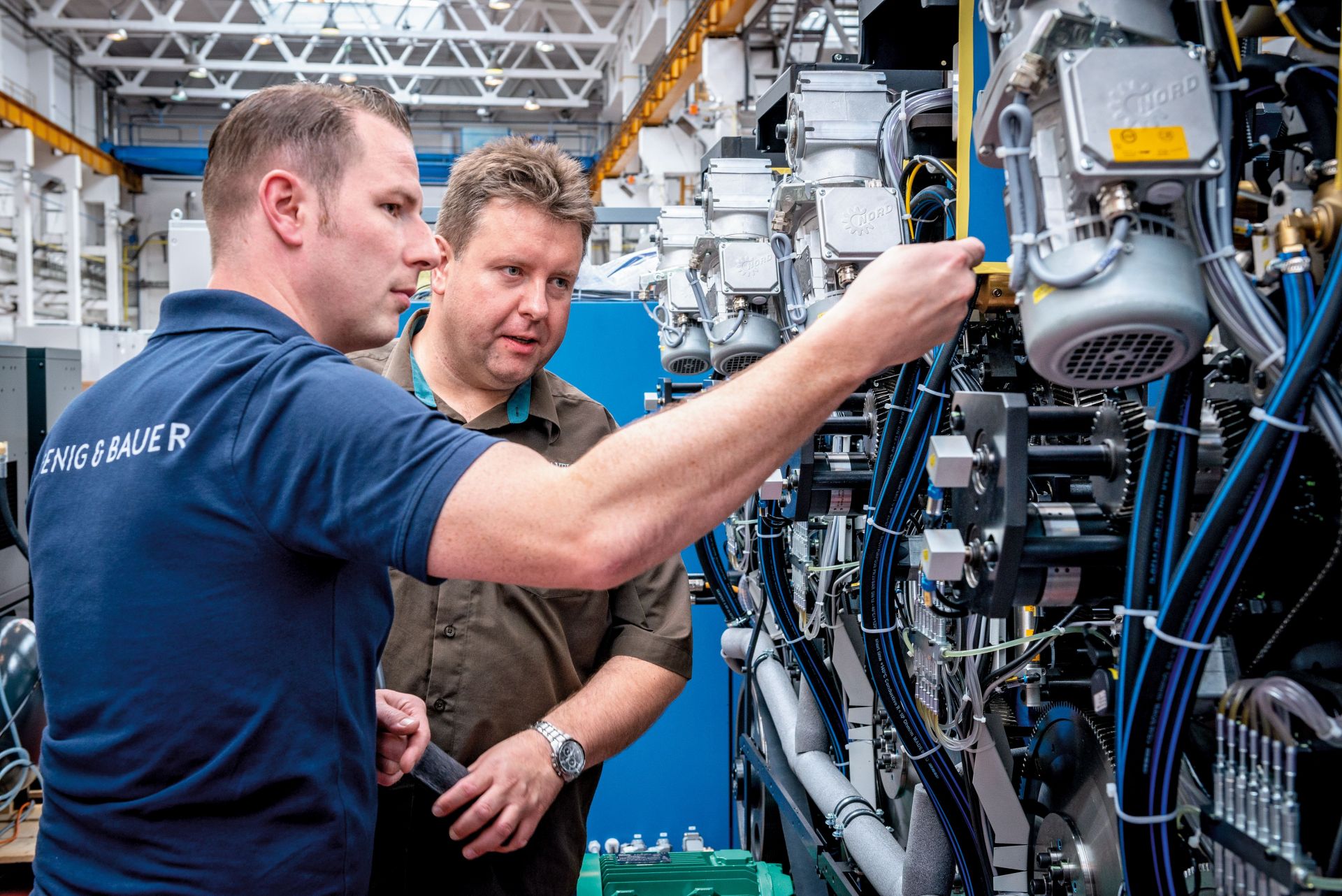

Matthias Herrmann discusses technical details of the half-format Rapida with Benjamin Nelles (left). The final assembly hall in Dobruška is an ideal place for such explanations, as presses and subassemblies are available in all states of completion.

One camera, three functions: Inline colour control, sheet inspection and comparison of the printed sheet with a pre-press PDF

Martin Dänhardt

Background photo: To mark the visit by Matthias Herrmann (left), the Rapida 76 printed an individually designed poster. Peter Kolle, sales director at Koenig & Bauer Sheetfed (centre), and sales manager Christofer Hugel from Koenig & Bauer (DE) presented a specially framed print.