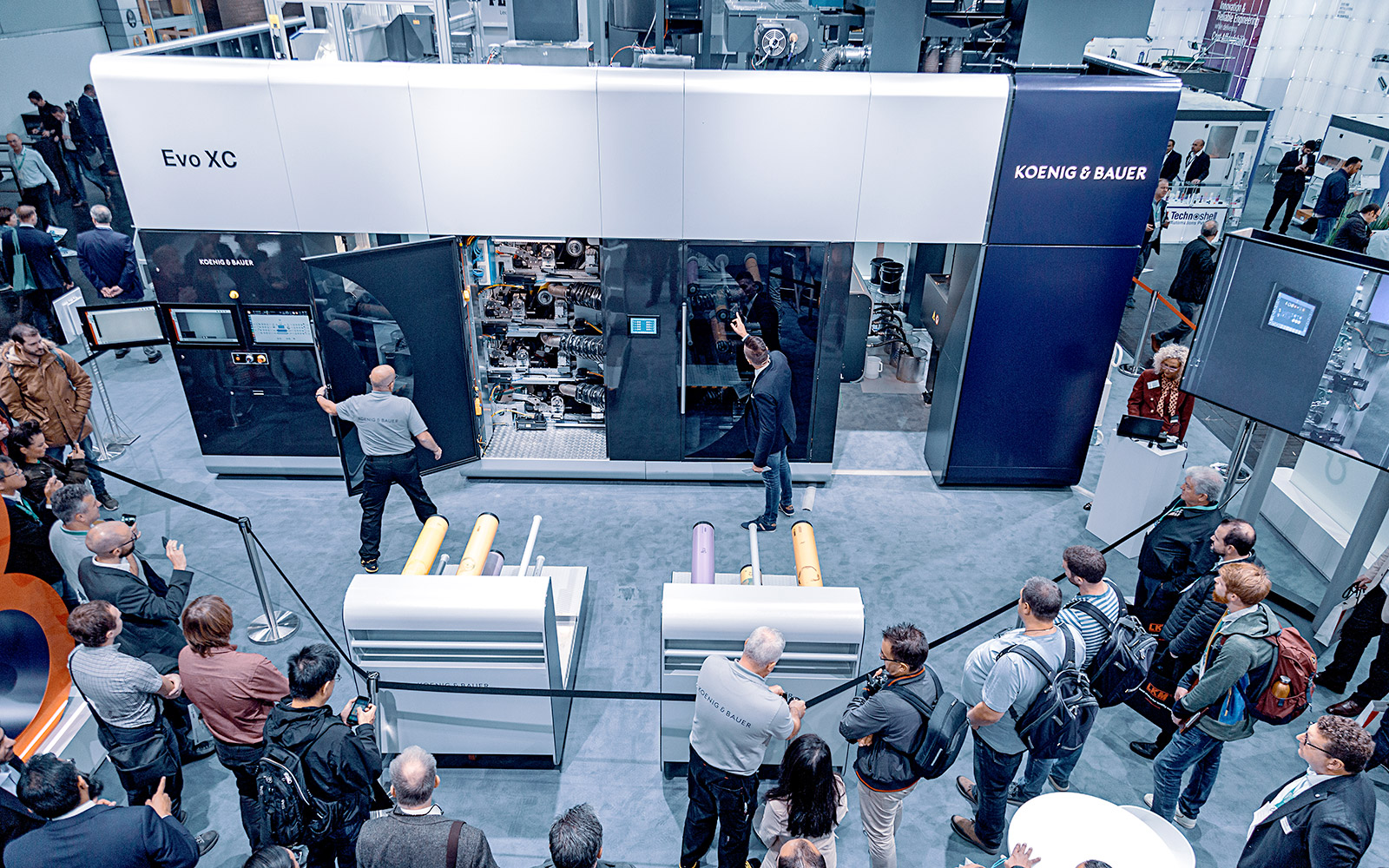

Newly developed compact CI flexo press from Koenig & Bauer Flexotecnica

Compact Evo XC sets new standards

Koenig & Bauer Flexotecnica is launching an extremely compact and highly productive CI flexo press as the latest addition to its already well-established Evo series.

The new Evo XC is to be offered in two different standard versions, both characterised by an exceptionally compact design, and provides for maximum repeat lengths of up to 850mm (33.5in), depending on the version chosen. Printing speeds up to 400m/min (1,312ft/min) are possible. For a number of years, we have observed sustained growth in packaging printing. Around three-quarters of all flexible packaging produced in Europe is printed, and flexo printing accounts for the lion’s share. Stable growth in this segment is driven by current trends. These include not least the increases in singleperson households and online shopping. At the same time, packaging is unequivocally a brand ambassador. Product cycles are also becoming shorter, and the numbers of different product variants continue to grow as product individualisation gains popularity. As a consequence of this fast-moving change, print jobs are becoming shorter and more individual. In order to safeguard economic success, print companies are in the meantime seeking new ways to enhance efficiency and productivity while nevertheless reducing investment outlay. In this context, reduced space requirements, high performance and fast job changeovers play a decisive role. The circular economy places ever higher demands on modern printing companies. Alongside conventional substrates, they are also increasingly required to print recyclable and biodegradable materials. The Evo XC was designed to facilitate an efficient printing and drying process when using environment-friendly water-based inks, not only on paper, but also on plastic films. Koenig & Bauer’s specially developed Energy Saving Package is a sustainable technical solution enabling energy recovery during production. This represents a far from insignificant contribution to the sparing use of natural resources.

Koenig & Bauer Flexotecnica presented its new extremely compact and highly productive 8-colour CI flexo press for the first time at the K 2019 trade fair

To meet today’s market demands, the extremely compact CI flexo press Evo XC has been designed with the smallest possible footprint, enabling installation alongside the wide-web machines in an existing hall without necessitating additional building investments. The new Evo XC series is offered in a basic version with eight printing units for printing widths from 620 to 1,020mm (24.4 to 40.2in) and in an enlarged version for printing widths from 820 to 1,420mm (32.3 to 55.9in). Thanks to the traditionally robust engineering, high stability and durability are also guaranteed in production with medium run lengths. Particular attention was paid to ease of operation when designing the press. The Evo XC incorporates innovative technology solutions for highly efficient drying. The chosen drying tunnel concept is at the same time the key to both minimised space requirements and considerable energy savings in the drying process itself. The latest generation of the AIF system permits faster makeready, reduces start-up waste, and in doing so provides for enhanced productivity and optimised availability. This innovative solution is achieved through automatic control of the correct impression position with a minimum of material waste, thus enabling a faster and more efficient production start. The new press control functionality is fully integrated into a new HMI with touchscreen operation for simple and intuitive handling. Another special feature is the facility to perform all impression adjustments simultaneously and thus in next to no time on all printing units. It goes without saying that this new press series can also be used in conjunction with the award-winning service tool AR-DataGlass, which implements simple and direct communication between the customer and Koenig & Bauer to accelerate the rectification of any production disturbances. This serves to reduce downtimes and maintenance costs to a minimum.

Henning Düber

Background photo: Newly developed compact CI flexo press from Koenig & Bauer sets new standards in the industry