Investment in ten-colour Rapida 106 LED-UV coater press at ICP Roto on La Réunion

Products with added value thanks to Rapida 106 LED-UV

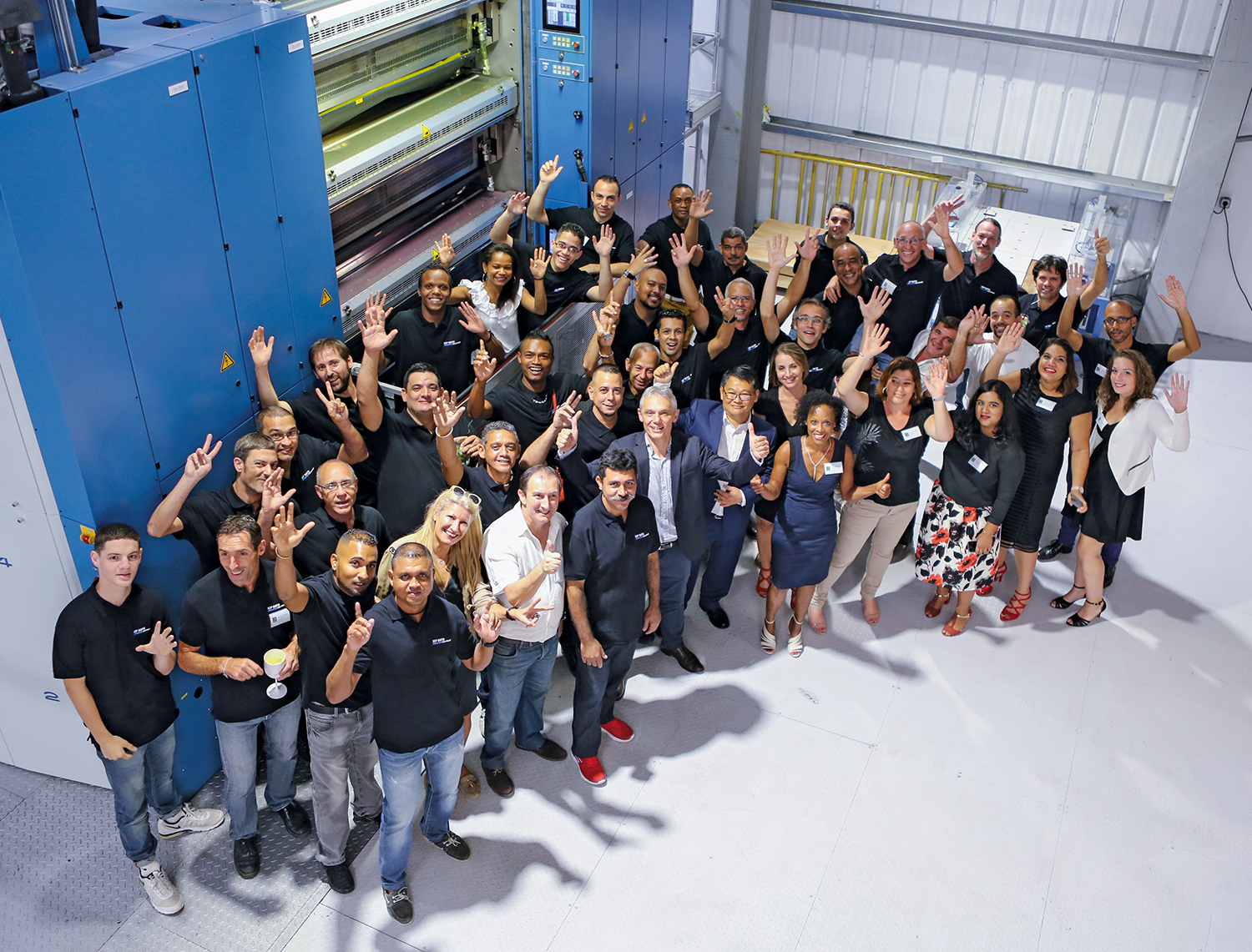

The printing company Imprimerie du Sud has been based in Saint Pierre on the French island of La Réunion since 1985 and belongs to the ICP Roto Group, a highly respected commercial and newspaper printing house which operates both web and sheetfed offset presses

ICP Roto currently employs a workforce of 46 and posted turnover amounting to €16m ($17.7m) for the business year 2018/2019. As part of a project to expand and modernise its machinery base, the company management recently decided to invest €5m ($5.5m) in the purchase of a new sheetfed offset press and peripheral equipment such as a folding machine and die-cutter. At the end of 2019, a Rapida 106 with ten printing units, coater, perfecting unit, reel sheeter and LED-UV dryers will be making its entry in a brand new building erected for Imprimerie du Sud. The new Rapida is replacing a 16-page web press and will be printing a wide range of high-quality publications and advertising materials.

Different types of press for the most varied print products

Philippe van Damme, technical director at ICP Roto: “The Rapida 106 is just one element of a much more extensive programme of investments aimed at further development of our Saint-Pierre location. The plan is to expand our existing means of production, the centrepiece of which is our Cortina from Koenig & Bauer, with further innovative technologies.” The Cortina installed in 2017 is a modern and flexible offset press in 64-page format. It runs entirely without dampening solution and the critical additives this entails, and has enabled ICP Roto to attract a multitude of new orders, especially for magazines with relatively low circulations.

“Our production is today primarily advertising brochures,” says Philippe van Damme, “but we intend to shift the balance in favour of publications. We have already gained significant market shares in this segment since the arrival of the Cortina, because we can now produce magazines in runs from 5,000 copies both profitably and at a competitive price. At the same time, we want to be able to offer our customers products with added value. And this gap in our portfolio will soon be closed by the Rapida 106, which can produce fully coated covers, publications with five-colour printing on both the front and back sides, and – thanks to the LED-UV technology – even high-quality brochures on uncoated papers or non-absorbent substrates.”

It was not least Koenig & Bauer’s outstanding implementation of the innovative LED-UV process, which ICP Roto was able to witness during a series of visits to French users who are already working with the technology, which convinced the responsible decision-makers.

The Rapida 106 LED-UV will be arriving at ICP Roto’s Imprimerie du Sud facility on the island of La Réunion in the Indian Ocean at the end of 2019

Improved competitiveness

Alongside expansion of the product portfolio, enhanced productivity through extensive process automation was another declared objective of the mammoth project. Philippe van Damme: “We are in permanent competition with printers on the neighbouring island of Mauritius, where the economic and social framework conditions are more favourable than here. If we are to bring jobs currently printed on Mauritius back to La Réunion, we must be able to offer competitive prices, which in turn requires highly automated machinery and processes.”

To meet such demands, the new press was configured with a so-called “high-speed package” which enables production at speeds up to 18,000sph in perfecting mode. Time-saving automation features, including fully automatic FAPC plate changers and CleanTronic Multi washing systems, define the Rapida 106 as a veritable job changeover champion. This effectiveness is backed up with modern measuring systems, such as Quali-Tronic ColorControl with DotView and Print Check, which scans every single printed sheet for colour and quality flaws, and ErgoTronic ColorControl with LAB, ACR and LogoTronic Professional. In this way, quality and productivity can be maximised, while waste is reduced to a minimum. Even the paper supply to the feeder is automated with a reel sheeter from Mabeg.

Ecology and sustainability

According to Philippe van Damme, ecology and sustainability are firmly anchored in the corporate philosophy: “The installation of the Cortina in 2017 transformed our production processes and has enabled us to reduce paper and energy consumption significantly. The new sheetfed offset press is now to follow in the same vein.” In fact, the Rapida 106 integrates seamlessly into this master plan. Thanks to the new LED-UV technology, powder is no longer required and there are significant energy savings because the dryers no longer generate unwanted heat. A further benefit is the reduced expenditure for maintenance thanks to the greatly extended service life of the LED lamps. The installation of an automatic ink supply system using 200-litre barrels similarly contributes to process optimisation and waste avoidance.

The entire ICP Roto team in front of the Cortina, which has enabled the company to open up promising new markets, especially in the field of low-circulation magazines

Looking ahead to the future

“We can look optimistically to the future,” says Philippe van Damme. “The potential is there, but you must also have a vision and stand out from the crowd. To be successful nowadays, it is imperative to integrate the latest technologies into your work processes and to invest according to a carefully considered strategy. ICP Roto doesn’t work with suppliers, but with partners. Koenig & Bauer is one of our long-standing partners and has earned our great appreciation with its dependability, the quality of its products and the excellent service provided by its staff.”

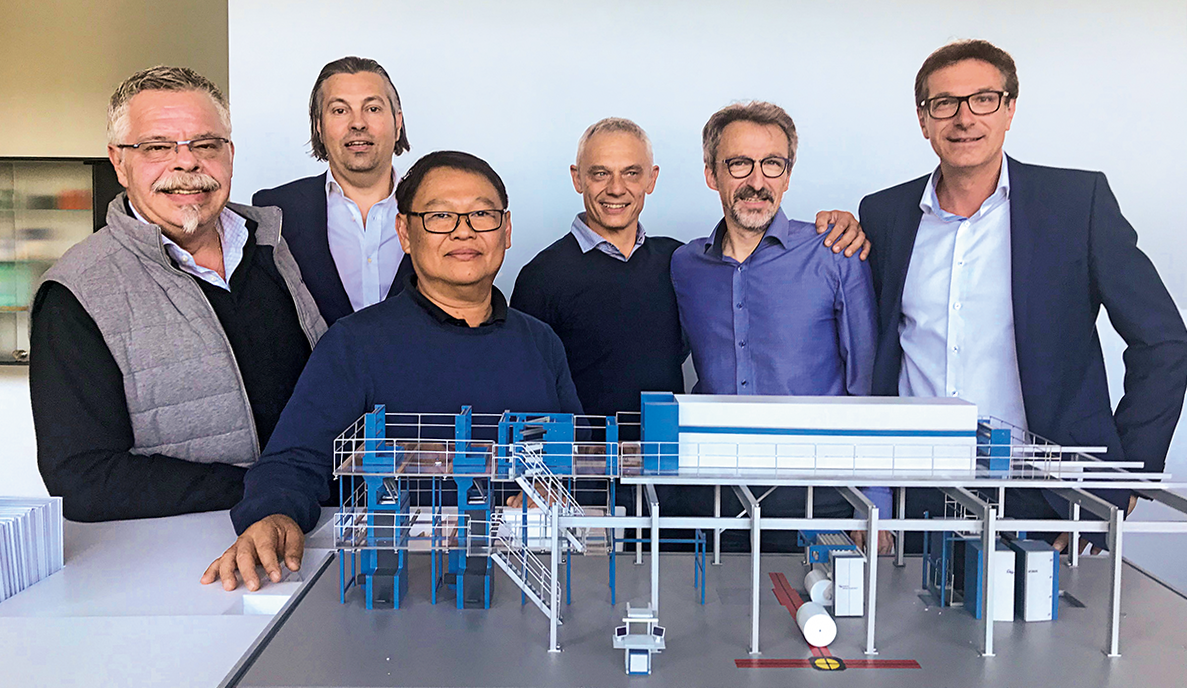

Alfred Chane-Pane, managing director of ICP Roto (third from left), and technical director Philippe van Damme (third from right) show off a model of their Cortina press line, accompanied by staff from long-standing partner Koenig & Bauer

Sarah Herrenkind