Imprimerie Bellêmoise in Western France is investing in a five-colour Rapida 105 with inline finishing capabilities

Exclusive print products thanks to LED-UV

Imprimerie Bellêmoise, a print company based in Normandy and a member of the Renard Group, commissioned its first printing press from Koenig & Bauer, a five-colour Rapida 105 with an inline coater and LED-UV capabilities, in spring 2019.

The new sheetfed offset press produces a wide range of print products that create added value for the customer, and is fully consistent with the company’s deep commitment to sustainability and environment-friendly printing.

Commercial printer since 1898

When Georges Lavayer founded Imprimerie Bellêmoise in 1898, his company was a small family-run business specialised in letterpress printing, primarily producing local advertisements and notary proclamations. In 1966, the company was acquired by Guy Baron, moved to the premises spanning more than 1,000m² (10,760sq.ft) which it still occupies today, and invested in its first offset presses. When the company merged with Jacques Bihel in 1987, its machinery was modernised once again and the small family business was transformed into a widely acclaimed specialist for technically demanding brochures, enjoying with a sound reputation among suppliers of luxury goods. Towards the end of the 1990s, a general economic crisis put acute financial pressure on the company, resulting in its most recent acquisition by its present owner, Michel Renard, in 2003. Renard industrialised production, introduced automation and established standardisation processes. The Renard Group today comprises three production units, each with its own very specific product and customer typology, and employs a total workforce of 70, with 24 of those employees based at Imprimerie Bellêmoise.

A bold decision

In 2018, the Renard Group decided to invest in a new printing press, and its final decision fell in favour of a five-colour Rapida 105 with LED-UV capabilities and the CX equipment package, allowing heavier substrates with a thickness of up to 1.2mm (0.047in) to be used. Configured with the inline colour measuring and control system QualiTronic ColorControl, which scans every single sheet and issues colour control commands after every ten sheets, the new high-performance press was installed at Imprimerie Bellêmoise in spring 2019. “First of all, the investment was necessary to safeguard the future of our printing operations,” says production manager Anthony Chartier. “At the same time, however, we wanted to expand our product portfolio and establish a lead over our competitors by offering technically sophisticated products with high added value, which explains our decision to choose the LED-UV technology and an inline coater. Sometimes, you have to make a bold decision to be successful.” The Rapida 105 is just one element within a comprehensive investment project which includes also a new Bograma die-cutter, a folding machine with interposer unit from H&H, and a new CtP system. Anthony Chartier: “A new press was necessary to systematically expand our product portfolio, but not sufficient in itself. We also needed to modernise our post-press equipment in order to be able to offer our customers innovative products.”

Productivity, flexibility and added value

Taking stock after eight months of full production, the overall verdict is highly positive. Anthony Chartier: “We are fully satisfied with our Koenig & Bauer press. Around 15 per cent of the products we are able to offer today would not have been feasible with a typical offset press. The special equipment that our Rapida features allows us to print in flwless quality on all sorts of different substrates: coated and uncoated papers, board, laminated paper or non-absorbent films, for example. We are now in a position to produce sealed brochures with supplements, window films and carton packaging. There is great demand for new products like these from our customers. We are outsourcing far fewer jobs to subcontractors, and the coater allows us to realise fantastic effects, for example drip-off finishes, which lend our products an unbelievable added value. Furthermore, thanks to the LED-UV technology, we have been able to improve our production processes and delivery times. The fact that the printed sheets dry immediately has helped us to reduce production times to such an extent that we are now in a position to ship an order for 500 copies of a brochure in less than 24 hours. That is a game-changer for our daily work practices, and also for those of our customers.”

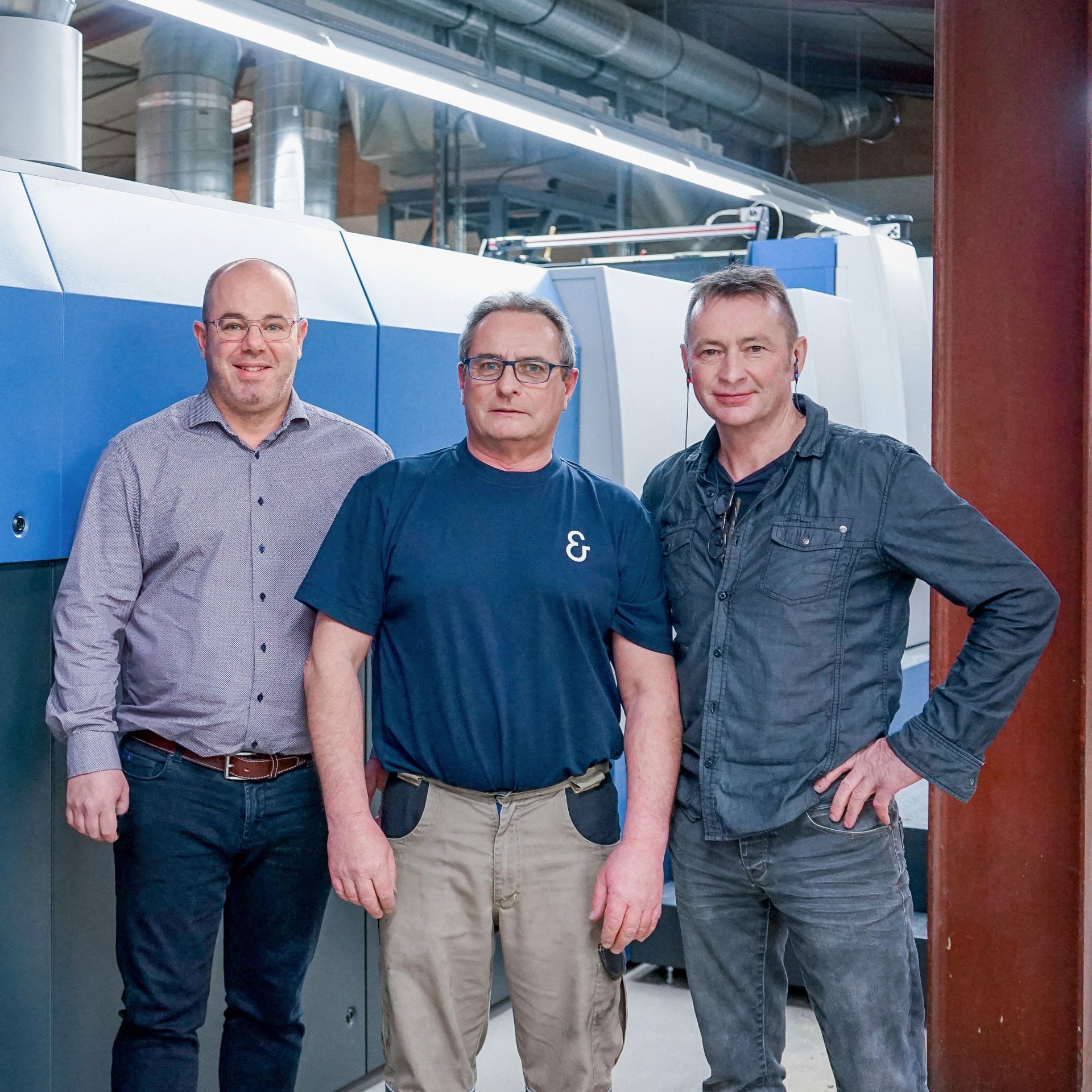

The team at Imprimerie Bellêmoise in front of their first Koenig & Bauer press (l-r): Production manager Anthony Chartier, printer André Ripeaux and team leader Pascal Hérault

LED-UV and sustainability

The Renard Group has been championing sustainability in print since 2007, as confirmed by a variety of certificates and labels: Imprim’Vert, PEFC and ISO 9001. This is why it was so important that the new press also reflect these values. Anthony Chartier: “When we learned that Citeo, the French institute for paper recycling, was applying a 5 per cent penalty to all UV print products from 2019 on, we were really impressed, because eco-friendly production is a matter close to our heart, and because we are convinced of the benefits of the LED technology for the environment. LED-UV allowed us to reduce our power consumption, eliminate powder and reduce our use of coated papers. We therefore sat down with our different suppliers and obtained ‘INGEDE 11’ certificates, which confirm the good deinkability of paper printed using LED-UV. This has enabled our customers to be exempted from the 5 per cent penalty.”

Sarah Herrenkind

Background photo: The Rapida 105 can print up to 16,000 sheets per hour and boasts unbelievable substrate flexibility – from coated 80gsm paper to 1.2mm board, uncoated papers and non-absorbent films, everything is possible